Welcome to the Help Center

When contacting Support, please provide detailed information about your account and issue so we may assist you well.

Call

Phone: 866-374-7877

Monday to Friday:

8AM to 5PM Central

Frequently Asked Questions

Expand the menus below for more details

We’d love to hear from you! To make it easy for you we have a few different ways for you to contact us.

- Email: To email us, please use our email [email protected]

- Phone: Our phone number is 866-374-7877. You can speak to an agent Monday through Friday 8:00am - 8:00pm EST.

-

Postal mail: If you’d prefer to write us the old-fashioned way, our address is:

MINI PAK'R®

1 Graham Way

Hopkinsville, KY 42240

Please have your order number and your email in which you placed your order. Track your order HERE.

If you place your order by 3:00pm Central it will ship the same day.

After 3:00PM Central it will ship the next day.

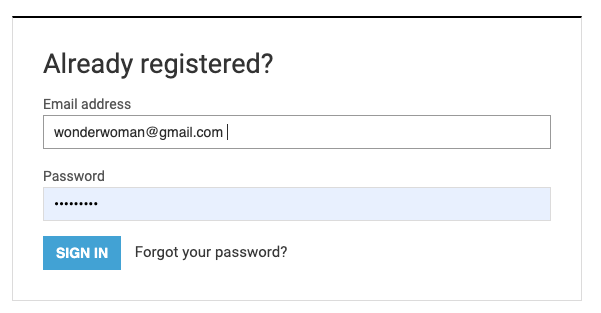

You can change your address by logging into your account @MINI PAK'R and navigate to the address section found here: https://store.minipakr.com/account/addresses

If you don’t remember the username or password for your MINI PAK'R membership, don’t panic! You can retrieve your username here, and reset your password here.

You’ll receive an email from us during the retrieval/reset process, so if you don’t remember the email associated with your account, or if you no longer have access to it, please call us at 1-888-646-4757. Our Member Support agents are available Monday through Friday 8:00am - 8:00pm CST.

You may view and download a digital version of the manual here: MINI PAK'R MANUAL

Or feel free to reach out and request a physical copy by the following:

Email: To email us, please use our email [email protected]

Phone: Our phone number is 1-888-454-5895. You can speak to an agent Monday through Friday 8:00am - 8:00pm CST.

Postal mail: If you’d prefer to write us the old-fashioned way, our address is:

MINI PAK'R

1 Graham Way

Hopkinsville, KY 42240

Forms of payment:

American Express

Discover

MasterCard

Visa

PayPal

We are sorry your item didn't arrive, or arrived broken. We are here to make it easy for you we have a few different ways for you to contact us.

We will need your account information and order number. You can find your order number by going here: ORDER

Email: To email us, please use our email [email protected]

Phone: Our phone number is 1-888-454-5895. You can speak to an agent Monday through Friday 8:00am - 8:00pm EST.

Postal mail: If you’d prefer to write us the old-fashioned way, our address is:

MINI PAK'R®

1 Graham Way

Hopkinsville, KY 42240

Error Code Guide

Click on an error code below to learn more

How to install the Support Arm for MINI PAK'R Quilt films.

How to replace the blade on the MINI PAK'R.

How to change film rolls on the MINI PAK'R.

How to replace the blade on the MINI PAK'R.

What Air Transfer Technology looks like in an Air Cushion

It is 14 inches / 36 cm long; 13 inches / 33 cm wide; and, 11 inches / 28 cm high. The MINI PAK’R® machine weighs 13 pounds / 6 kg, without film.

Here is a visual of the MINI PAK'R machine next to a Ball Jar.

Yes. The keypad provides a simple “+” or “-” adjustment that will increase the length of cushions up to 99 linear feet.

The MINI PAK'R® machine makes seven different cushions.

One Machine, 11 films.

See our different film configurations here: FILMS

The machine dispenses film at speeds up to 25 feet/7.6 meters per minute.

This “smart” machine “reads” an RFID tag on the film core and automatically sets the rate of air fill and the sealing temperature. The machine contains a small electric air blower that receives predetermined inflation and sealing instructions from the RFID label.

No. The MINI PAK’R® machine is meant to be used with only with MINI PAK'R® film products.

Yes. The key pad allows for a slight seal temperature adjustment – up or down. This is normally unnecessary since the machine automatically sets the seal temperature and seals the film.

How to fix this error:

Make sure that the roll is not loaded backwards. The film should unwind off the top of the roll. Correct by turning the film roll so that film unwinds off top of roll toward operator.

Unwind at least 18″ of film off the roll before trying to thread it through the air tube.

Pull the film as far down the air tube as possible. Press and HOLD the START button. The drive motor will advance until the button is released. Continue to pull the film until it emerges from the front of the machine. Release the START button.

Turn off the machine and remove the power. Open the top cover (a screwdriver is required). Look into the machine for a film jam on the air tube around the seal bar or the slitter blade. If small amount of film is jammed on the air tube, use the eraser end of a long pencil to push the film up or down the air tube until it is completely out of the machine. Close the cover. Restore the power and turn the machine on. Load the film normally.

The slitter blade is dull or broken. Replace the blade per the instructions in the User Manual.

The heater bar is in the UP position. Turn the machine off and back on again to reset the heater assembly to the DOWN position.

- Are you sure that power is available in the power outlet?

- Is the power cord plugged into the power outlet?

- Is the power cord plugged into the back of the machine?

- Is the switch on the machine turned to ON (I)?

Yes. The key pad allows for a slight air fill adjustment – up or down. However, this is normally unnecessary since the machine automatically fills and seals the film.

How to fix this error:

The seal temperature is too low (very faint or light seal created). Increase the seal temperature by 5 points (degrees) at a time up to a maximum of +15 points.

The seal temperature is too high (very wide seals with many holes created). Decrease the seal temperature by 5 points (degrees) at a time down to a minimum of -15 points.

Air fill is too high. Decrease the air volume by 5 points (5 percent) down to a maximum of 20 points.

How to fix this error:

The roll is not properly mounted on the roll holder.

- Firmly push on the end of the film roll to make sure it is fully inserted onto the roll holder.

- Press STOP/RESET.

- Wait for a RDY display.

- Operate the machine normally.

How to fix this error:

The roll is not properly mounted on the roll holder.

- Firmly push on the end of the film roll to make sure it is fully inserted onto the roll holder.

- Press STOP/RESET.

- Wait for a RDY display.

- Operate the machine normally.

Visit our How To Pack video page for more details.

Click HERE to view our Privacy Policy.

Click HERE to view our Terms of Use.

Click HERE to view our Return Policy.

Privacy Notice

We ask that you read this privacy notice carefully as it contains important information on who we are, how and why we collect, store, use and share personal information, your rights in relation to your personal information and on how to contact us and supervisory authorities in the event you have a complaint.

Who we are

Pregis Limited collects, uses and is responsible for certain personal information about you. When we do so we are regulated under the General Data Protection Regulation which applies across the European Union (including in the United Kingdom) and we are responsible as ‘controller’ of that personal information for the purposes of those laws.

The personal information we collect and use

Information collected by us

In the course of the supply of packaging systems and solutions we collect the following personal information when you provide it to us:

• Key contact details within the organization for the purpose of sales, purchasing, service and support activities inclusive of address and location details.

How we use your personal information

We use your personal information to:

• Ensure continuous relevant communication for day to day trading activities.

• Keep you up to date with relevant commercial offerings, developments and other items of relevant legitimate interest to you and/or your organization.

Who we share your personal information with

We routinely share names and delivery address details with our trusted third party suppliers for the purpose of goods delivery or in the support of goods and services supplied. Some of those third party recipients may be based outside the European Economic Area — for further information including on how we safeguard your personal data when this occurs, see ‘Transfer of your information out of the EEA’.

We will share personal information with law enforcement or other authorities if required by applicable law.

We will not share your personal information with any other third party.

Whether information has to be provided by you, and if so why

The provision of name, contact details and delivery address is required from you to enable us to provide the supply of packaging systems, solutions and other relevant services. We will inform you at the point of collecting information from you, whether you are required to provide the information to us. Pregis Ltd Unit 1 | The io Centre | Arlington Business park Stevenage | Herts | SG1 2BD +44 (0) 1438 740649 | www.pregiseu.com |[email protected]

How long your personal information will be kept

• We will hold name, address and contact details for the period of the ongoing business relationship and for no more than 6 years thereafter, as we are required to retain this information by applicable UK tax law (currently 6 years)

Reasons we can collect and use your personal information

There are a number of lawful reasons where personal information can be used (or 'processed'). One of which is called 'legitimate interests'.

Broadly speaking Legitimate Interests means that your personal information can be processed if:

We have a genuine and legitimate reason and we are not harming any of your rights and interests

This means when you provide your personal details to us we use your information for our legitimate business interests to continue to improve our service and products. Before doing this we will carefully consider and balance any potential impact on you and your rights.

Some typical examples of when we might use the approach are for preventing fraud, direct marketing, maintaining the security of our system, data analytics, enhancing, modifying or improving our services, identifying usage trends and determining the effectiveness of our campaigns.

Transfer of your information out of the EEA

We may transfer your personal information to the following which are located outside the European Economic Area (EEA) as follows:

• Pregis LLC (Pregis Limited’s Parent company) and suppliers or partners thereof within the USA for the purpose of the supply of goods or support services that you or your organization have ordered or engaged.

Such countries do not have the same data protection laws as the United Kingdom and EEA. Whilst the European Commission has not given a formal decision that the USA provide an adequate level of data protection similar to those which apply in the United Kingdom and EEA, any transfer of your personal information will be subject to a European Commission approved contract (as permitted under Article 46(5), which the Article 29 Working Party guidance confirms must be specified of the General Data Protection Regulation that are designed to help safeguard your privacy rights and give you remedies in the unlikely event of a misuse of your personal information. To obtain a copy of such safeguards see website ico.org.uk

If you would like further information please contact us (see ‘How to contact us’ below). We will not otherwise transfer your personal data outside of the EEA or to any organization (or subordinate bodies) governed by public international law or which is set up under any agreement between two or more countries.

Your rights

Under the General Data Protection Regulation you have a number of important rights free of charge. In summary, those include rights to:

• access to your personal information and to certain other supplementary information that this Privacy Notice is already designed to address

Pregis Ltd Unit 1 | The io Centre | Arlington Business park Stevenage | Herts | SG1 2BD +44 (0) 1438 740649 | www.pregiseu.com |[email protected]

• require us to correct any mistakes in your information which we hold

• require the erasure of personal information concerning you in certain situations

• receive the personal information concerning you which you have provided to us, in a structured, commonly used and machine-readable format and have the right to transmit those data to a third party in certain situations

• object at any time to processing of personal information concerning you for direct marketing

• object to decisions being taken by automated means which produce legal effects concerning you or similarly significantly affect you

• object in certain other situations to our continued processing of your personal information

• otherwise restrict our processing of your personal information in certain circumstances

For further information on each of those rights, including the circumstances in which they apply, see the Guidance from the UK Information Commissioner’s Office (ICO) on individuals rights under the General Data Protection Regulation.

If you would like to exercise any of those rights, please:

• email, call or write to us.

• let us have enough information to identify you (eg account number, user name, registration details),

• let us have proof of your identity and address (a copy of your driving licence or passport and a recent utility or credit card bill), and

• let us know the information to which your request relates including any account or reference numbers, if you have them If you would like to unsubscribe from any email newsletter you can also click on the ‘unsubscribe’ button at the bottom of the email newsletter. It may take up to 30 days for this to take place.

Keeping your personal information secure

We have appropriate security measures in place to prevent personal information from being accidentally lost, or used or accessed in an unauthorized way. We limit access to your personal information to those who have a genuine business need to know it. Those processing your information will do so only in an authorized manner and are subject to a duty of confidentiality.

We also have procedures in place to deal with any suspected data security breach. We will notify you and any applicable regulator of a suspected data security breach where we are legally required to do so.

How to complain

We hope that we can resolve any query or concern you raise about our use of your information.

The General Data Protection Regulation also gives you right to lodge a complaint with a supervisory authority, in particular in the European Union (or European Economic Area) state where you work, normally live or where any alleged infringement of data protection laws occurred. The supervisory authority in the UK is the Information Commissioner who may be contacted at https://ico.org.uk/concerns/ or telephone: 0303 123 1113. Pregis Ltd Unit 1 | The io Centre | Arlington Business park Stevenage | Herts | SG1 2BD +44 (0) 1438 740649 | www.pregiseu.com |[email protected]

Changes to this privacy notice

This privacy notice was published on 25th May 2018 and last updated on 25th May 2018.

We may change this privacy notice from time to time, when we do we will inform you via email.

How to contact us

Please contact us if you have any questions about this privacy notice or the information we hold about you.

If you wish to contact please send an email to [email protected] or write to Pregis Limited, Unit 1, The io Centre, Whittle Way, Stevenage, Hertfordshire UK or call +44 (0)1438 740649.

1 Year Limited Warranty for MINI PAK'R™

Thank you for registering your MINI PAK’R® Air Cushion Machine to be eligible for your one (1) year limited warranty. Please email any additional questions you may have to: Customer Service at [email protected] or call +1-888-646-4757

MINI PAK’R® Air Cushion Machine, Accessories, and customer kits Limited Warranty.

What does this limited warranty cover?

MINI PAK’R® warrants the MINI PAK’R® air cushion machine, accessories, and Customer Kits against defects in material and workmanship for a period of one year from the date you purchased the machine/product, as stated on your sales or delivery receipt.

Replacement parts and machine/product are warranted to be free from defects in material and workmanship for 90 days or for the remainder of the applicable warranty period for the parts or machine/product they are replacing or in which they are installed, whichever is longer.

This warranty applies only if you are the original end-user purchaser and is not transferable. You will be asked to provide proof of purchase as a condition of receiving warranty service. For MINI PAK’R® machines, accessories and customer kits under this warranty, MINI PAK’R® will, at its sole option, repair or replace any defective part or machine/product with a functionally equivalent new or factory-reconditioned part or machine/product.

MINI PAK’R® will have no obligation to repair or replace any MINI PAK’R® parts or machine/product until you return the defective product to MINI PAK’R®. MINI PAK’R® will be responsible for all transportation risks and costs in connection with this warranty service.

What will we do to correct problems?

This Limited Warranty covers any defects in material or workmanship under normal use during the Warranty Period. During the Warranty Period, MINI PAK'R will repair or replace, at no charge, products or parts of a product that proves defective because of improper material or workmanship, under normal use and maintenance.

How long does the coverage last?

The Warranty Period for Physical Goods purchased from MINI PAK'R is 365 days from the date of purchase. A replacement Physical Good or part assumes the remaining warranty of the original Physical Good or 365 days from the date of replacement or repair, whichever is longer.

What does this limited warranty not cover?

This Limited Warranty does not cover any problem that is caused by:

Conditions, malfunctions or damage not resulting from defects in material or workmanship

What do you have to do?

To obtain warranty service, you must first contact us at [email protected] to determine the problem and the most appropriate solution for you.

EXCEPT AS EXPRESSLY SET FORTH IN THIS LIMITED WARRANTY, MINI PAK'R MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. FPI EXPRESSLY DISCLAIMS ALL WARRANTIES AND CONDITIONS NOT STATED IN THIS LIMITED WARRANTY. ANY IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW ARE LIMITED IN DURATION TO THE APPLICABLE WARRANTY PERIOD.

Some states or countries do not allow a limitation on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages for consumer products, or of a consumer’s statutory rights. In such states or countries, some exclusions or limitations of this Limited Warranty may not apply to you. This Limited Warranty is applicable in all countries and may be enforced in any country where MINI PAK'R or its authorized service providers offer warranty service.

This Limited Warranty does not apply to (1) expendable or consumable parts, including injector blades and Teflon seal belts and tape; (2) normal wear from regular use of the MINI PAK’R machine; (3) any product with the serial number removed; (4) any MINI PAK’R machine that has been operated with non-MINI PAK'R film; or (5) any product if damaged or defective due to (a) accident, misuse, abuse, contamination, improper or inadequate maintenance or calibration or other external causes; (b) software, interfacing, parts or supplies not supplied by MINI PAK'R; (c) loss or damage in transit; or (d) modification or service by other than MINI PAK'R I or an MINI PAK'R-authorized service provider.

For service that MINI PAK'R performs that is not covered under this Limited Warranty, MINI PAK'R will charge its standard time and material rates.